Have any questions?

+44 1234 567 890

The Robustness

The Pawert-SPM briquetting presses are constructed in robust design from the ground up..

High densification pressures are required in production of our premium briquettes with a high density. The rugged Pawert-spm presseshandle effortlessly these considerable pressures and loads.

That means the sleeves, the slide and its giude, the crankshaft, the connection rod, etc. are subject to very high load and therefore designed very robust.

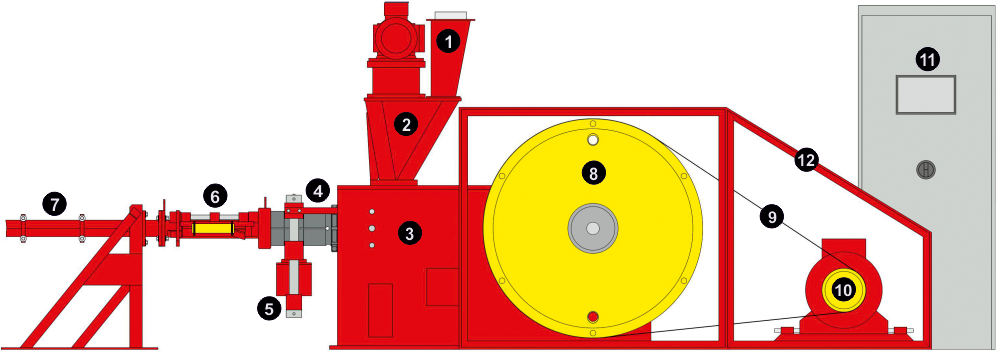

Components of the press

| 1 | Raw material supply |

| Connecting tube for raw material feeding. | |

| 2 | Twin screw feeding |

| To increase the capacity as well as compression. Special raw material mixing technology in fron of the ram. | |

| 3 | Frame |

| High quality welded steel construction, stress-free annealed for heavy-duty continous operation. | |

| 3 | Crankshaft |

| The heart of the machine, gorged from special steel with grinded crankshaft pins. | |

| 3 | Slide |

| Special graphite cast iron with hand-scraped cross head. The design of the cross head is trapeze-shaped to transmit the forces onto lines for a maintanance-free continuous operation. | |

| 3 | Bush bearing |

| Special bronze for best sliding properties and a long endurance. Crankshaft bearing derived from ship engine production. | |

| 4 | Press cylinder |

| Made of heavy duty steel, integrated channel system for heating- and cooling and equipped with press tools existing of 3 pressing steps with a length of 760mm. | |

| 5 | Hydraulic frame |

| Enables regulating the pressure on the 3th pressing step during production to compensate variations within the raw material. | |

| 6 | Safety flap |

| Operater protection and production start-up aid. | |

| 7 | Cooling line |

| Exact guide conveying of the briquette string and cooling of it under light pressure. Reduction of the press impulse. | |

| 8 | Flywheel |

| Cast iron with a Diameter of 1'400mm and a weight of approx. 1'200kg/fly wheel. Total flywheel mass approx. 2'400kg. | |

| 9 | Drive belt |

| Flat belt - absorb the press impulse. | |

| 10 | Drive motor |

| Electric motor | |

| 11 | Electrical cabinet |

| SPS controlled with monitoring and display of all important operatimng parametersg. | |

| 12 | Protective coating |

| Personal protection |

Single Head Briquetting Press

|

Type |

|

|

|

|

I-75/200 |

I-85/200 |

I-90/200 |

|

|

Briquetting diameter (mm) |

|

|

|

|

75 |

85 | 90 | |

| Capacity (kg/h) | |||

| 700 - 900 1'000 - 1'200 |

900 - 1'100 1'100 - 1'300 |

1'000 - 1'200 1'300 - 1'500 |

for private use for industrial use |

| Weight of the press (kg) | |||

|

7'500 |

|||

| Driving power (kWh) | |||

|

55 |

|||

Data sheet Single Head Briquetting Press

Double Heat Briquetting Press

| Type | |||

| II-75/200 | II-85/200 | II-90/200 | |

| Briquetting diameter (mm) | |||

| 75 | 85 | 90 | |

| Capacity (kg/h) | |||

| 1'400 - 1'800 2'000 - 2'400 |

1'800 - 2'200 2'200 - 2'600 |

2'000 - 2'400 2'600 - 3'000 |

for privat use for industrial use |

| Weight of the press (kg) | |||

| 10'500 | |||

| Driving power (kWh) | |||

| 110 | |||

Data sheet Double Head Briquetting Press

Briquetting Saw

|

Type |

|

06-V2 |

|

Briquetting diameter (mm) |

|

75 - 90 |

|

Capacity (kg/h) |

|

1'400 |

|

Weight of the saw (kg) |

|

1'000 |

|

Saw electrical engine (kWh) |

|

6 |

Data sheet Briquetting Saw